Performing fatigue analysis on nozzles using PV Elite is a simple process. Let us go through these steps to bring your fatigue information into PV Elite.

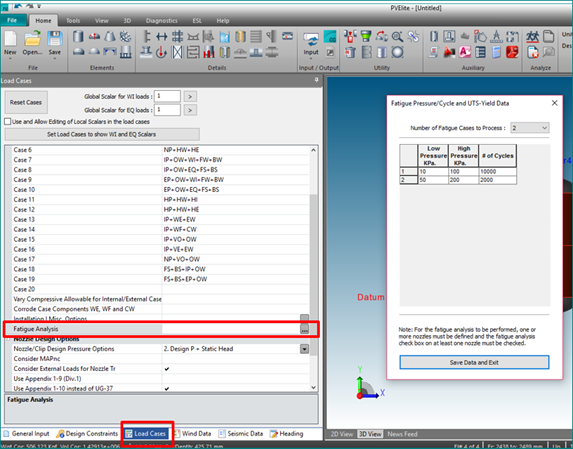

Once the Load Cases tab is active, click on the button that is next to ‘Fatigue Analysis’ and the Fatigue Pressure/Cycle Data Input screen appears. In the box at the top called ‘Number of Fatigue Case to Process,’ enter the number of cases you want considered. Then enter the pressure range and number of cycles for each range. Finally, click on the button at the bottom of the screen that says ‘Save Cases and Exit.’ At this point, PV Elite has all the information it needs to perform the fatigue analysis on any nozzles you add to your model.

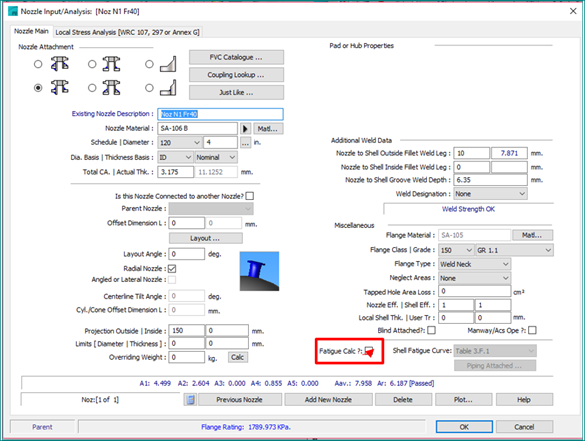

Go back to the General Data Input tab where you find your model on the screen. When you add a nozzle to the vessel using the usual nozzle input screen, notice that at the bottom of screen the check box ‘Fatigue Calc ?’ Make sure this box is checked, see below:

Now, for the PD5500 and EN13445 models, the drop down list labeled ‘Weld Class’ beside the check box becomes active. Choose a suitable letter (see PD 5500 Annex C for details concerning fatigue classes). Note, class C is the least severe, and W the most severe. Enter the rest of your nozzle data, ensuring the nozzle is adequately reinforced in the normal way.

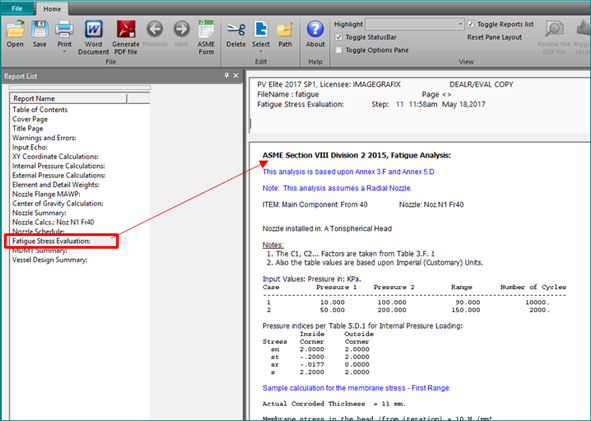

When you have finished entering your vessel data and have completed building your model, you can press the calculation button (running man). The output processor will include a fatigue analysis report. That report will contain the full analysis for all of the nozzles on which you indicated to perform fatigue analysis: